[Kamakura] Experience making accessories at Work Studio Ruka!

Kanagawa ・ Kamakura teeth Lined with delicious gourmet spots Komachi Street and power spots Tsurugaoka Hachimangu Shrine , Great Buddha of Kamakura A popular tourist destination with plenty of attractions .

This time, Kamakura's stylish workshop " Work Studio Ruka " Activity Japan Editorial Department I & Editorial Department U Report on the accessory making (silver ring making) experience To do!

Why not use this experience report as a reference and have some fun making accessories in Kamakura?

table of contents

- 1 What is Work Studio Ruka?

- 2 Silver ring making experience at Work Studio Ruka

- 3 Preparation for accessory making experience

- 4 Accessory making lecture begins

- 5 Started making silver rings

- 6 During the experience, you will be given information about Kamakura.

- 7 Make your own silver accessories at Work Studio Ruka!

- 8 Feature articles recommended by the editorial department

What is Work Studio Ruka?

"

Work Studio Ruka

"teeth

6 minutes walk from Kamakura Station

The workshop located at

.

Silver Ring

or

Silver bangle

of

Accessory making

You can experience.

- 4.8

- (9 reviews)

- Kanto

- Kanagawa

- Kamakura

- Handmade accessories/accessory making

- Metal engraving experience/metal engraving class

Work Studio Ruka is a jewelry studio located on Yuigahama Street, a 6-minute walk from Kamakura Station. The studio is housed in an old house that has been renovated into a wedding ring studio, and is popular for its fantastical yet relaxing atmosphere. The workshop is run by a skilled craftsman who has worked for a jewelry brand for many years, and is one of the best in the industry for the number of processes involved and its serious approach. This is perfect for those who want to create something original and want to work hard!

Silver ring making experience at Work Studio Ruka

This time Activity Japan editorial department Hands-on silver ring making experience death, Interview The we !

- 4.6

- (4 reviews and experiences)

◆Experience Overview◆Contents: You will create a ring using silver 950 material (width 2mm, 3.5mm, 5mm). There are various finishing methods such as mirror finish, matte finish, and black oxidized finish. The cost does not change regardless of the size or width! Price: 5,800 yen *Tax included, material costs, engraving and finishing fees are also included. Price revised from January 2026: 6,200 yen

"

Work Studio Ruka

"When you enter,

Very stylish atmosphere

.

"Each staff member has their own specialty, be it photography, painting or planting, and they work to create a space and atmosphere that makes the space comfortable."

That's what they say.

Pretty colored glass covering the entire wall or Light , Photos and Paintings , Flower The sense is wonderful. !

this day is Two female staff members ( Yamamoto-san, a professional jewelry craftsman Others) are supported They will do it for you.

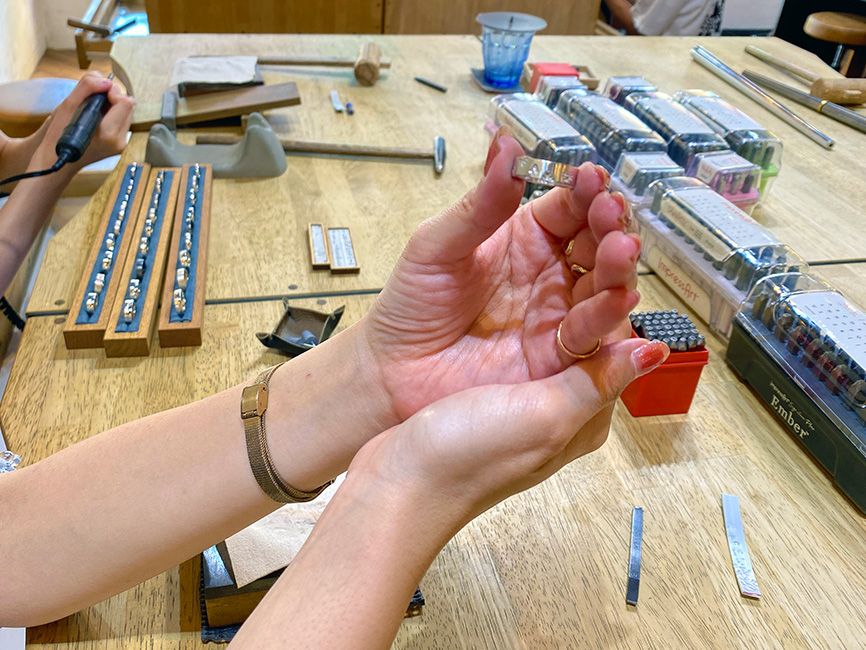

On the desk Already ready .excited!

Preparation for accessory making experience

Finally

Silver ring making begins

!

First,

Determine the width of the ring

.

The width size is

2mm

,

3.5mm

,

5mm

of

3 types

.

The width of the ring

I'll try on the samples and then decide.

.

The wider the width, the easier it is to add a design (engraving) and the more options you have. that's why, Both of them chose 5mm this time. .

Once the width size is decided, " Ring gauge Using Ring size We will decide .

"Which finger should I put the ring on?" I, an editor at Activity Japan, pondered while using a gauge.

After some hesitation,

I decided on size 9, which I think I can use on my middle finger and thumb together.

!

Once you have decided on the width and size of your ring, Change into the apron provided. Ready !

Accessory making lecture begins

During the lecture, together with other guests The flow of the experience and how to use each tool Such, Easy to understand and detailed explanation Receive .

The editorial staff listens to the explanation with concentration.

First

Explanation of the accessory making process

will be received.

The process is

mainly

Design (Engraving)

,

Bending work

,

Welding (brazing)

,

Polishing

of

Four

.

next Description of tools All the tools used in the experience are authentic.

The desk

Engraving desk

(A dedicated work desk for craftsmen to make rings)

.

It's interesting that it's at eye level when you're sitting down to make it easy to work in, the top is curved, and there's a drawer to collect scraps!

continue

Explanation of the materials used for the ring

.

During the explanation, the staff will prepare the silver material that matches the thickness and size you decided on earlier.

The silver material

Silver alloy 950 silver

.

It is neither too soft nor too hard, making it easy to handle.

That's what they say.

next How to use various hammers about.

Hammer The following three types are used To do.

- Hammer for creating the hammered pattern

- Engraving hammer

- A hammer to straighten materials that tend to bend during work.

First Use practice materials do, Practice stamping (patterns) with a hammer to hold.

Activity Japan editorial staff I and U were a little nervous about using the hammer, which they were not used to.

First,

Practice using a hammer to create a hammered pattern

.

The size of the hammer marks differs between the left and right sides of the hammer.

So I practice both.

The hammer hits the material directly, It's pretty hard to hit where you're aiming !

It went well!

Continuing to practice engraving fart.

Design pattern on the tip of the stick (stamp)

You can stick whatever you like on it.

To prevent the markings from shifting

Check the position from the side,

Support with four fingers

,

Swing the hammer down forcefully from above about five times.

The point is

.

Once you have practiced to your satisfaction, The real thing is about to begin is.

Started making silver rings

Using the engravings and samples as a reference, we expand on the design image. .

Many engraving designs including alphabets, numbers, patterns, etc. Activity Editorial Department I and Editorial Department U look at the picture and wonder what to do.

First, the word "SILVER" is engraved on the back of the ring.

The "SILVER" mark is a quality guarantee.

So be sure to include it!

Maybe I didn't have enough strength, or maybe it slipped from where I was holding it.

The word "SILVER" is now tripled. Lol

That's part of the charm of it, since it was the first engraving I did myself.

While thinking of the design in your head, you can then engrave the back of the piece.

Notepad and pen are also provided.

So,

If you are a careful or particular person, we recommend writing down the design image on a note before engraving.

is.

(By the way, the two of us immediately started playing.)

On the back People often include the date, initials, or the text (words) they want to engrave. That's what they say.

Editorial Department I, to commemorate the day

I decided to include the date (2024.7.2).

!

However, I made a mistake and put in the number L instead of 7... I kept making mistakes, but I told myself that this was also a good memory.

Once the back side is done,

Now onto the engraving on the front

.

Since this is a part that can be seen directly, you need to be careful not to get the top and bottom mixed up and to use the right amount of pressure, while you strike and check the carving...

I'm gradually getting used to it and I'm starting to hit the ball well!

Hammered pattern as desired If you also add Engraving design is complete !

next To make it into a ring shape, The process of bending silver (material) is.

"

Ring Bender

"using,

Make the shape closer to a circle.

.

The material (silver) is bent by

This task requires more strength and skill than it looks.

!

Once you've worked hard to round it up to this point, The craftsman will make the final adjustments. .

Just when you think it's nicely curled up, I made the adjustments by cutting the gaps with a jigsaw. .

Even though I cut it, it somehow fits perfectly. Truly a master craftsman !wonder is.

continue Welding (brazing) work fart .

Soldering agent (small silver chips)

Put it on the stove and heat it up with a gas burner...

It melts and seeps into the gaps.

!

The staff will soak it in chemicals, let it cool, and then remove any oxide film and dirt.

next, While striking the ring with a mallet against the iron rod, Final size adjustment .

If the ring is still more distorted than expected, you can use a mallet to shrink it and bring it closer to your size.

It's ready when there is no gap between the ring and the iron core rod!

Our staff will help you make the final adjustments.

Finally Polishing fart!

Since we use an electric file, If you have long hair, it's a good idea to tie it up to prevent it from getting caught in the hair. !

By changing the fineness of the electric file...

It's getting brighter and brighter !

Front and back, Once you are satisfied with the finish, the work is complete. !

Finally, a special machine is used. Polishing Finish I will have them do it.

After having the dirt thoroughly removed with an ultrasonic cleaner...

Finally, the original ring is complete. !

I was able to experience almost all of the steps myself and was very satisfied with the finished product!

You will be filled with a sense of accomplishment.

This time, editorial staff I and U, Each Matte finish and Glossy finish I chose this, so the finished product is different and interesting. !

The finished piece can be easily wiped with a cloth for care,

Enjoy the changes that occur over time, which is one of the joys of silver accessories.

That's what they say.

I'm looking forward to the changes that will come in the future.

I gradually got the hang of how to use a hammer, I want to try making rings and bangles with different designs and finishes again. !

During the experience, you will be given information about Kamakura.

The experience lasts about two hours, and staff will add finishing touches to each step, so there will be some waiting time.

The staff members were busy with their work. They will teach you about jewelry making, as well as tourist and gourmet information in the area. So you'll have fun and never get bored!

Photo

A Kamakura gourmet book hand-made by our staff

!

It was created by actively exploring the surrounding area, taking photos, and exchanging information.

That's what they say.

The bookshelves are also stocked with tourist information magazines about Kamakura.

While experiencing making silver accessories, It's also great to be able to get local information about Kamakura That's right!

After the experience, we had lunch at a soba restaurant that was actually recommended to us, and were very satisfied with the delicious soba and the lovely atmosphere of the old-style house.

Make your own silver accessories at Work Studio Ruka!

The "silver ring making" experience that I had the opportunity to experience this time was, There is a wide range of choices from engraving design to finishing. You can create a one-of-a-kind original ring in about 2 hours. The appeal is !

From ring design to shaping, welding and polishing You can do most of the steps yourself For, I love the work even more now. Yo.

A professional jewelry craftsman will teach you each step of the process very carefully and will kindly support you when you have any problems.

No worries even if it's your first time or you're clumsy

!

I was also happy that the two staff members were friendly and talked to us about the production and local information about Kamakura.

The inside of the workshop is also stylish

I wanted to take lots of photos.

!

Whether you're on a girls' trip or as a couple, why not enjoy making silver rings and bangles and create unforgettable memories of your trip to Kamakura?

The plan for "Work Studio Ruka" that we visited this time

This plan does not support English.

◆Experience Overview◆Contents: You will create a ring using silver 950 material (width 2mm, 3.5mm, 5mm). There are various finishing methods such as mirror finish, matte finish, and black oxidized finish. The cost does not change regardless of the size or width! Price: 5,800 yen *Tax included, material costs, engraving and finishing fees are also included. Price revised from January 2026: 6,200 yen

This plan does not support English.

◆Experience Overview◆Contents: You can make a bangle made of silver 950. There are various finishing methods such as mirror finish, matte finish, and black smoke processing! Stone setting options are also available! Please consult with the staff on the day. Price: From 6,200 yen (including material cost, finishing, and consumption tax) ★ The production cost varies depending on the width. ・Width 2.0 mm ¥ 6,200 ・Width 3.5 mm ¥ 6

- 4.8

- (9 reviews)

- Kanto

- Kanagawa

- Kamakura

- Handmade accessories/accessory making

- Metal engraving experience/metal engraving class

Work Studio Ruka is a jewelry studio located on Yuigahama Street, a 6-minute walk from Kamakura Station. The studio is housed in an old house that has been renovated into a wedding ring studio, and is popular for its fantastical yet relaxing atmosphere. The workshop is run by a skilled craftsman who has worked for a jewelry brand for many years, and is one of the best in the industry for the number of processes involved and its serious approach. This is perfect for those who want to create something original and want to work hard!

*The content of this article is current as of July 2024.

![[Zushi] Experience SUP at Feather Factory!](https://img.activityjapan.com/wi/zushi-feather-factory_thumb.jpg)

![[2025] When will the beaches in the Shonan area open? Images of recommended beaches and activities](https://img.activityjapan.com/wi/shonan-beach-opening_thumb.jpg)

![Soba-making experience date | Recommended classes [Tokyo, Kamakura, Nagano] images](https://img.activityjapan.com/wi/soba-making-date_thumb.jpg)

![Kanto area sightseeing spots [Recommended day trips] images](https://img.activityjapan.com/wi/kanto-going-out_thumb.jpg)